Sourcing faucets from China offers immense opportunities for your business. But how do you find a good faucet supplier in China amidst a vast market? This guide is your roadmap. It provides a step-by-step process to identify a reliable partner, ensuring quality, compliance, and a smooth supply chain. To see what a top-tier supplier looks like, explore our capabilities at Blue Sea Industrial.

Step 1: Identifying a Genuine Faucet Manufacturer vs. a Trading Company

Your first challenge is distinguishing a true manufacturer from a trading company. Partnering directly with a China faucet factory offers better prices, greater control, and deeper technical collaboration. But how can you be sure of their identity?

Key Signs of a True Manufacturer

Genuine manufacturers often have a substantial online presence showcasing their factory. Look for detailed information about their production facilities. They should be able to provide specific technical data about their processes. A strong history, like our 27 years in the business, is another key indicator.

Why Direct Factory Partnership Matters

A direct partnership streamlines communication. It allows for more effective OEM collaboration and faster problem-solving. You gain access to engineering expertise for custom designs. This direct link is crucial for building a successful product line.

Questions to Ask Potential Suppliers

Ask about their annual production capacity. Inquire about their primary export markets. Request details about their in-house manufacturing processes. A reliable manufacturer will answer these questions with confidence and specific details. How do they handle quality control at each stage?

Step 2: Evaluating Quality Control and In-House Manufacturing Capabilities

A supplier’s commitment to quality is paramount. A truly reliable faucet supplier will have a robust quality control system integrated into every step of their production. What should you look for?

The Importance of Raw Material Inspection (e.g., Low-Lead Brass)

High-quality faucets start with high-quality materials. A top manufacturer will have strict inspection protocols for incoming raw materials like brass. They must ensure it meets standards for low lead content. This is crucial for health, safety, and market compliance.

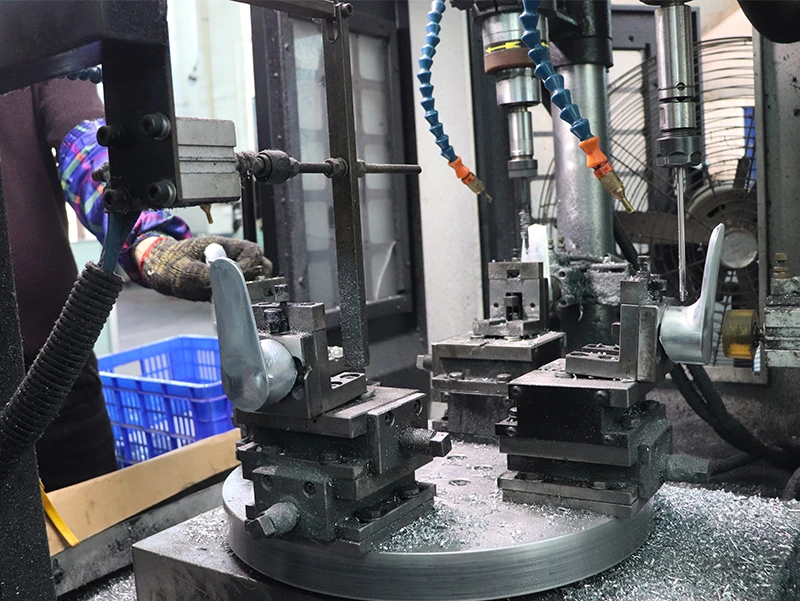

A Look into the Die-Casting and Machining Process

The precision of the die-casting and machining processes determines the faucet’s durability. Ask potential suppliers about the technology they use, such as CNC machining. This ensures every component fits perfectly, preventing leaks and ensuring smooth operation for years to come.

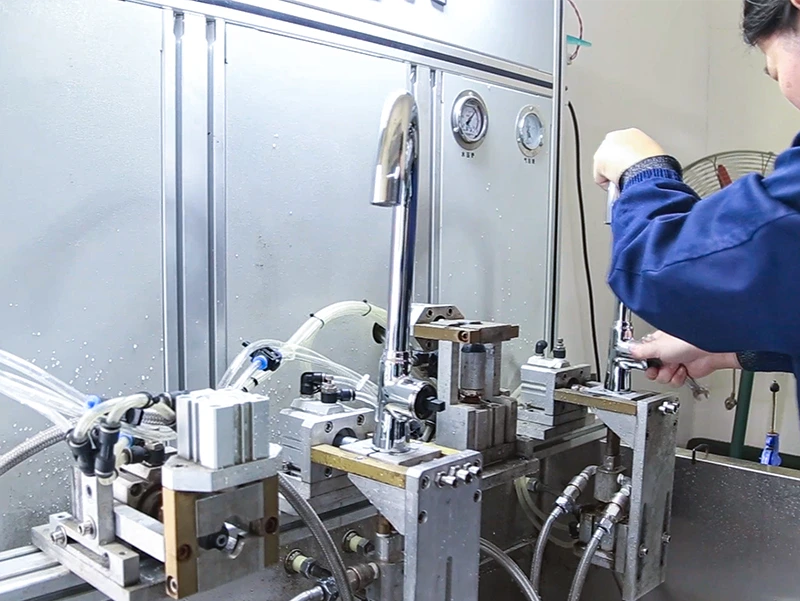

Essential Quality Checks: From Plating Thickness to Leakage Tests

Rigorous testing is non-negotiable. Manufacturers should perform multiple checks, including salt spray tests for corrosion resistance and pressure tests for leakage. Consistent plating thickness is also vital for a lasting finish. A transparent supplier will gladly share their testing procedures. This is how you ensure faucet quality.

Step 3: Verifying Global Certifications (cUPC, WRAS, ISO)

Certifications are your passport to international markets. Working with a supplier that holds key global certifications saves you time, money, and legal headaches. It’s a clear sign of professionalism and experience.

Understanding Key Certifications for Your Market

If you’re selling in North America, cUPC certification is essential. For the UK market, WRAS approval is required. The ISO 9001 certification demonstrates a commitment to quality management systems. A knowledgeable faucet manufacturer in China will understand these requirements.

How to Request and Validate Certificates

Always ask for copies of their certificates. You can then verify the certificate number and validity on the respective organization’s official website. A legitimate supplier will be transparent and provide this information without hesitation.

The Risks of Working with Non-Certified Suppliers

What are the risks of sourcing from China without certified products? Your products could be rejected by customs. You may face legal issues or product recalls. Ultimately, it can damage your brand’s reputation and lead to significant financial loss.

Step 4: The Art of Negotiation: Price, MOQs, and Payment Terms

Once you’ve shortlisted potential suppliers, the negotiation phase begins. This is about more than just getting the lowest price; it’s about establishing a fair and sustainable partnership.

Balancing Cost vs. Quality

The cheapest offer is rarely the best. Focus on value. A slightly higher price from a manufacturer with superior quality control and reliable service is a better long-term investment.

Understanding Minimum Order Quantities (MOQs)

Discuss MOQs early in the process. Some factories have high minimums, while others are more flexible, especially for new partners. A good partner will work with you to find a reasonable starting point.

Secure Payment Terms for International Trade

Standard payment terms often involve a 30% deposit and 70% balance before shipping. For new relationships, using secure payment methods like a Letter of Credit (L/C) can provide protection for both parties.

Step 5: Navigating Logistics and Shipping from Your China Faucet Factory

The final step is getting your products from the factory to your warehouse. A supplier with extensive export experience is invaluable in navigating the complexities of international logistics.

Choosing Between FOB, CIF, and EXW

Understand Incoterms. FOB (Free on Board) is a common and balanced choice for buyers. Your supplier handles the goods until they are loaded onto the vessel, and you control the main sea freight.

Essential Tips for Packaging and Damage Prevention

Proper packaging is crucial to prevent damage during transit. Your supplier should use sturdy, multi-layer cartons and appropriate inner packing for each faucet. This small detail reflects their overall professionalism.

Working with Freight Forwarders and Customs Clearance

An experienced supplier can often recommend reliable freight forwarders. They should also provide all necessary documentation for a smooth customs clearance process. This level of support is a hallmark of a great partner. To learn how an experienced team can help, visit our website to see our services.

Building a Lasting Partnership with Your Faucet Supplier

Sourcing faucets from China is a strategic process. It’s not about a single transaction but about building a long-term partnership. By focusing on identifying true manufacturers, verifying quality, and understanding the entire process, you can build a resilient supply chain. This approach ensures you receive high-quality products that will satisfy your customers for years to come. What are your biggest challenges when sourcing from China? Share your thoughts below!

Frequently Asked Questions (Domande frequenti)

How do I verify if a China faucet factory is legitimate?

Request their business license, factory address, and any quality certifications like ISO 9001. A legitimate manufacturer will also be open to a factory tour, either in person or virtually. A well-established online presence with detailed factory information is also a good sign.

Can a faucet manufacturer in China handle custom designs (OEM)?

SÌ, many leading manufacturers, like Blue Sea Industrial, specialize in OEM and ODM services. When you source faucets from China, you can provide your own designs and branding specifications. A good partner will have a dedicated R&D team to assist with development.

What are the typical lead times when sourcing faucets from China?

Production lead times can vary from 30 to 60 days, depending on the order size and complexity. This does not include shipping time. Always confirm lead times with your supplier during the negotiation phase to plan your inventory accordingly. For a better understanding of our capabilities, explore the Blue Sea Industrial difference.